Japanese

English

- 有料閲覧

- Abstract 文献概要

- 1ページ目 Look Inside

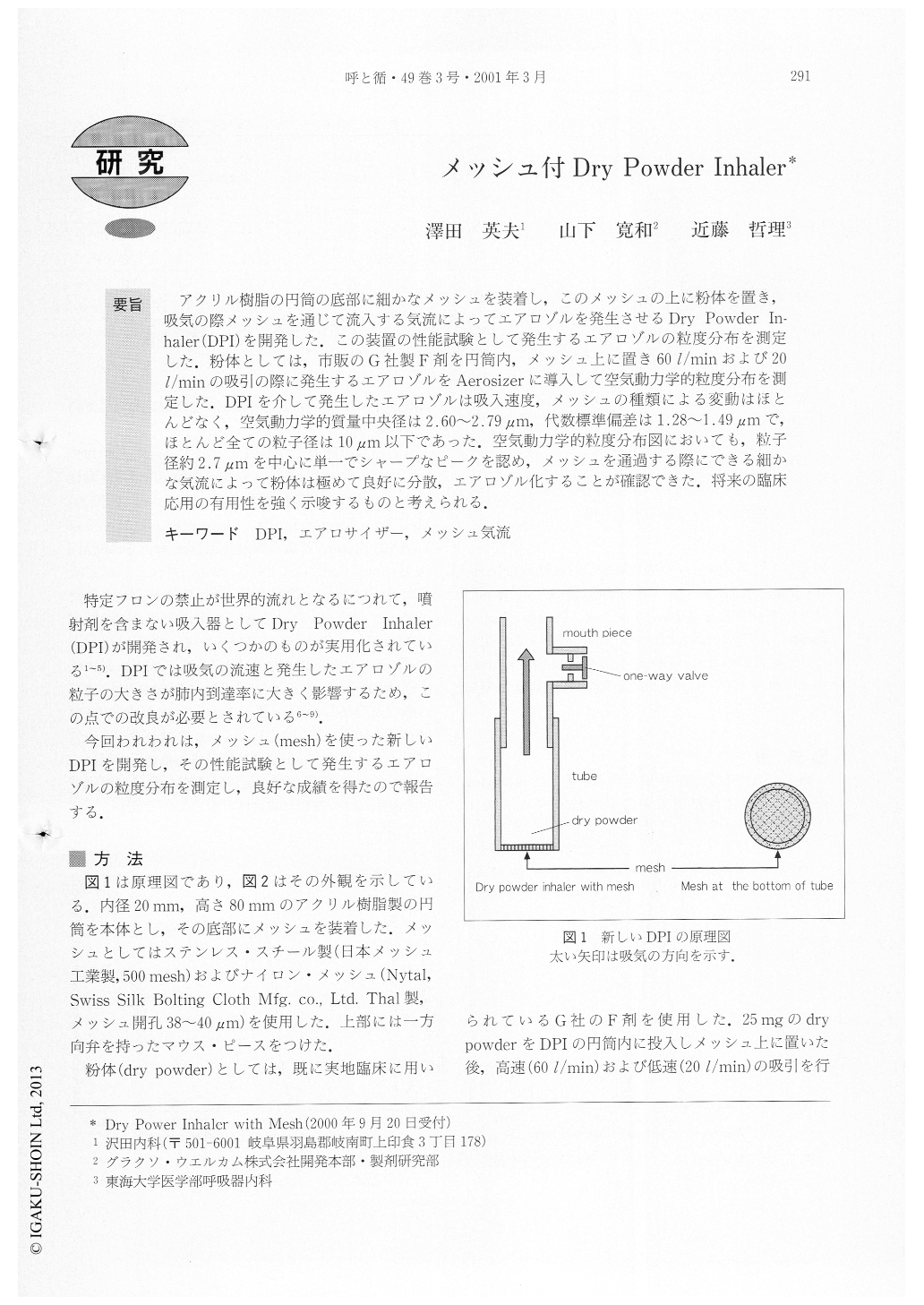

要旨 アクリル樹脂の円筒の底部に細かなメッシュを装着し,このメッシュの上に粉体を置き,吸気の際メッシュを通じて流入する気流によってエアロゾルを発生させるDry Powder Inhaler(DPI)を開発した.この装置の性能試験として発生するエアロゾルの粒度分布を測定した.粉体としては,市販のG社製F剤を円筒内,メッシュ上に置き60l/minおよび20l/minの吸引の際に発生するエアロゾルをAerosizerに導入して空気動力学的粒度分布を測定した.DPIを介して発生したエアロゾルは吸入速度,メッシュの種類による変動はほとんどなく,空気動力学的質量中央径は2.60〜2直79μm,代数標準偏差は1.28〜1.49μmで,ほとんど全ての粒子径は10μm以下であった.空気動力学的粒度分布図においても,粒子径約2.7μmを中心に単一でシャープなピークを認め,メッシュを通過する際にできる細かな気流によって粉体は極めて良好に分散,エアロゾル化することが確認できた.将来の臨床応用の有用性を強く示唆するものと考えられる.

A new dry powder inhaler was designed, consisting ofan acrylic resin tube with a fine mesh (500mesh) eitherof stainless steel or nylon at the bottom and a mouthpiece with a one-way valve at the top. We set 23mg ofdry powder provided from a commercial source on thebottom mesh in the tube and evacuated the dry powderat 20l/min and 60l/min to generate an aerosol. Theaerodynamic particle size distribution (APSD) of thisaerosol was measured with the Aerosizer.

The APSD of the aerosol generated from Our DPIshows a single, sharp peak of approximately 2.7μm inMass Median Aerodynamic Diameter and the GeometricStandard Deviation is less than 1.4km. When the drypowder was introduced to the Aerosizer without theDPI, the size of the particles generated was larger andmore widely distributed. The dry powder evacuatedwith the DPI at 20l/min showed almost the same pattern as at 60l/min, irrespective of stainless steel mesh ornylon mesh.

The new DPI generates fine and even-sized particles.The particle size is small enough to reach the peripheral airway free from deposition at the upper airway. Theexact mechanism of the particle dispersion is not clear,yet. All inspiratory air comes into the tube through themesh and the air stream was able to produce a gooddispersion of the particles. We conclude that the newDPI can generate selectively an aerosol with smallparticle size without high inspiratory flow rate. It ispotentially useful for inhalation therapy.

Copyright © 2001, Igaku-Shoin Ltd. All rights reserved.